Kislan Mechanical

Call Us! (732) 946-0928 info@kislanmechanical.com

Trenchless Technology

Licensed, Bonded & Insured

Master Plumber License BI 09484

LEED Accredited Professional

Call us to ask about our Warranty!

Piercing/Missile

Trenchless Water main/Service Technology

AVOID THE UNNECESSARY MESS AND RESTORATION COST ASSOCATED WITH CONVENTIONAL OPEN TRENCH UTILITY WORK.

Trenchless Technology is ideal for "NEW AND REPLACEMENT UTILITIES” water, gas, electric,communication and irrigation services with minimal surface disruption and is cost effective!

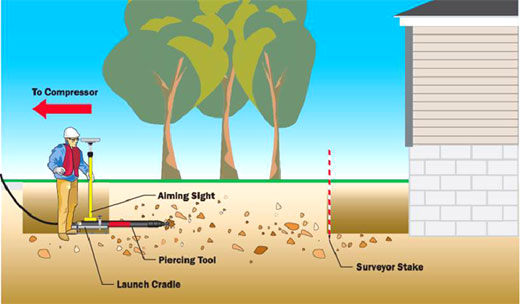

The Piercing / Missile Process

The piercing / missile process is relatively simple and involves a piercing tool sized to match the desired hole diameter and an air compressor.

An entry and exit pit is excavated to 10 times the diameter of the piercing tool. For example, a 3" (76 mm) tool would require two 30" (762 mm) deep pits. Once the pits are dug, the crew strings air hoses from the compressor to power the piercing tools. The piercing tool is connected to the air supply and positioned in the entry pits so that it is level to the ground and aligned directionally with the exit pit.

The piercing tool is then shot from the entry to the exit pit. The tool is driven forward by compressed air and bores on a path parallel to the ground. Once the bore is complete, piping conduit, up to the diameter of the piercing tool, can be placed in the hole. Average production is one foot per minute depending on ground conditions.

Stitch Boring

For longer bores, stitch boring can be utilized. This process involves excavating multiple entry and exit pits along the path of the bore. Each pit is spaced about 30' to 50' (9 to 15 m) feet apart. Once the pits are dug, the piercing tool is shot from pit to pit. The contractor can then stitch the conduit in the ground in similar fashion as the bores are completed; maintaining depth, accuracy and running line.

Stitch boring is one of the most economical trenchless methods to install large amounts of fiber where finished landscapes exist and short bores are the norm.

The Benefits of Trenchless Technology:

•Minimizes restoration cost associated with the replacement of driveways, patios, sidewalks, landscaping etc.

• Eliminates 85% of conventional open trench excavation and restoration.

• Cost effective

• Approved by authorities

• Green Technology

• Reduction of negative impact to property and infrastructures

• Non-invasive

• Innovation in new and replacement utilities

Conventional Water Services Disrupt Lawns, Sidewalks, Driveways, Sprinklers, etc.

Minimum Surface Disruption with Trenchless water main / service Technology.

The Rewards of Trenchless water main / service Technology: Minimal Restoration Required.